Maxi MSW

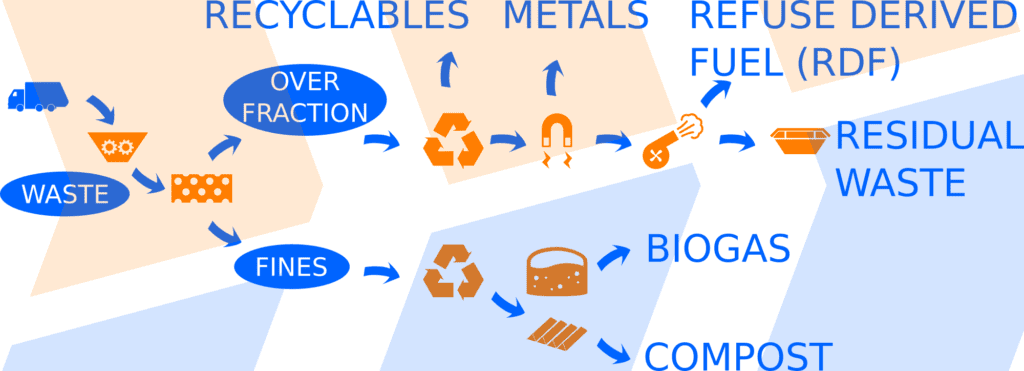

Approach

Based on waste quantity and composition, the targeted project outputs, your requirements and the project site, Surge will devise an optimal design.

In terms of inputs, we have experience with various waste streams such as municipal solid waste, commercial and industrial waste as well as source-separated but mixed recyclables.

Our approach for bespoke engineered waste sorting plants is as follows:

- Work closely with our clients to understand the project drivers and economics, offer advice based on our experience, and jointly come up with a concept that is workable.

- By creating a basic design, we transform the concept into a tangible solution; evaluating different options during this stage ensures the most feasible process is offered.

- With the price and details of all inputs and outputs at hand, jointly confirm the feasibility of the project with the client and lay out the plan for project execution.

Processes

We are not biased towards any process or technology, but instead select what is most suitable for the project. We have experience with the following unit operations:

Waste receiving

- Tipping floor

- Tipping pit

- Dosing bunker

Primary processing

- Primary shredding/bag opening

- screening (trommel/disc)

Recovery of recyclables

- Manual sortin

- Balers

- Magnets

- Eddy current separators for non-ferrous metals

- Ballistic separators

- Optical sorters

Organics treatment

- Anaerobic digestion (biogas)

- Composting

RDF production

- Wind sifter

- PVC removal

- RDF shredder

- Balers

Auxiliary

- Foul air treatment

- Weighbridges