Maxi Biogas

Approach

Based on the feedstock, desired project outputs, your requirements and the project site, we will come up with an optimal design.

In terms of inputs, we have experience with all suitable feedstocks, from chicken manure to water hyacinth, from abattoir waste to packaged food waste.

Our approach for bespoke engineered biogas plants is as follows:

- Work closely with our clients to understand the project drivers and economics, offer advice based on our experience, and jointly come up with a concept that is workable.

- By creating a basic design, we transform the concept into a tangible solution; evaluating different options during this stage ensures that the most feasible process is offered.

- With the price and details of all inputs and outputs at hand, jointly confirm the feasibility of the project with the client and layout out the plan for project execution.

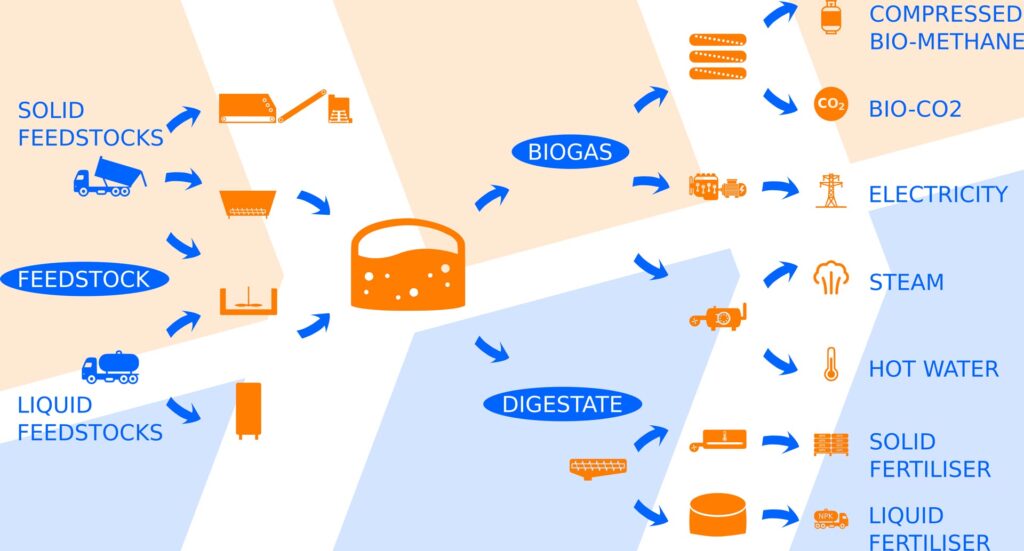

Processes

We are not biased in favour of any particular process or technology. Instead, we select what is most suitable for the project. We have experience in the following unit operations:

Feedstock preparation

- Storage & dosing

- Size reduction (milling, shredding, cutting)

- Disintegration (hammer mills, grinding)

- Conveying

- Pasteurisation

Feedstock de-packaging

- Separation mills

- Grit removal

- Reject dewatering

Digestion

- CSTR

- Plug flow

- Lagoon

Digestate treatment

- Dewatering

- Pasteurisation

- Drying

- Pelletising

- Evaporation

- Biological treatment

- Ammonia stripping

Biogas utilisation

- Desulphurisation

- Dehumidification

- Flaring

- Boilers

- Gas engine combined heat and power (CHPs)

- Biogas upgrading to bio-methane

- Bio-methane compression (Bio-CNG)

- Bio-methane liquefaction (Bio-LNG)

Auxiliary

- Control system

- Foul air treatment

- Weigh bridges

- Potable water supply

- Compressed air

- Boilers