Biogas FAQ's

What is biogas?

Biogas is a gaseous mixture of mainly methane (CH4) and carbon dioxide (CO2) formed by the breakdown of organic matter in anaerobic conditions.

What can be used as input materials for anaerobic digestion?

Virtually all organic matter is suitable for anaerobic digestion, except for wood. Examples of suitable feedstocks are:

- Manure: dairy and beef cow manure/slurry, chicken manure, pig slurry, goat manure, sheep manure

- Crop residue: maize/rice/wheat straw, stalks, pods, spoilt crops, sisal pulp

- Invasive plants: water hyacinth, cactus

- Energy crops: cactus, algae, grass

- Food processing waste: fruit and vegetable peels/pulp, whey, production overruns, out-of-specification products, floor sweepings (sugar, flour)

- Overdue shop returns: fresh produce, frozen foods, meat, pasta, cereal, baked goods, drinks, snacks

- Brewery waste: spent grain, spent yeast, brewery effluent

- Pure organics/food waste: vegetable market waste, kitchen waste

- Slaughterhouse waste: stomach/rumen content, blood, fat, organs, Dissolved Air Flotation (DAF) sludge, dead stock

- Sewage sludge

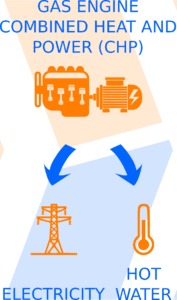

How can biogas be utilized?

The three main utilisation options are electricity generation, heat generation and upgrading of biogas to bio-methane.

Biogas is a flammable gas, so it can be used as the fuel for reciprocating engines (like those in cars) or gas turbines. The chemical energy embodied in the biogas is released during combustion and converted into mechanical energy, which in turn power generators to generate electricity.

As a flammable gas, biogas can be used to fuel boilers for hot water or steam generation, or for thermal drying.

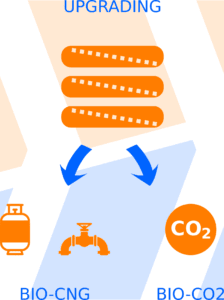

Biogas is largely a mixture of CH4 and CO2. By removing the bulk of the CO2, the remaining gas is virtually pure CH4. This is referred to as bio-methane.

Natural gas is also a methane-rich gas, thus bio-methane is equivalent to natural gas.

When compressed, natural gas is referred to as CNG, thus compressed bio-methane is referred to as bio-CNG.

Compressed bio-methane is energy-dense and is thus a suitable vehicle fuel.

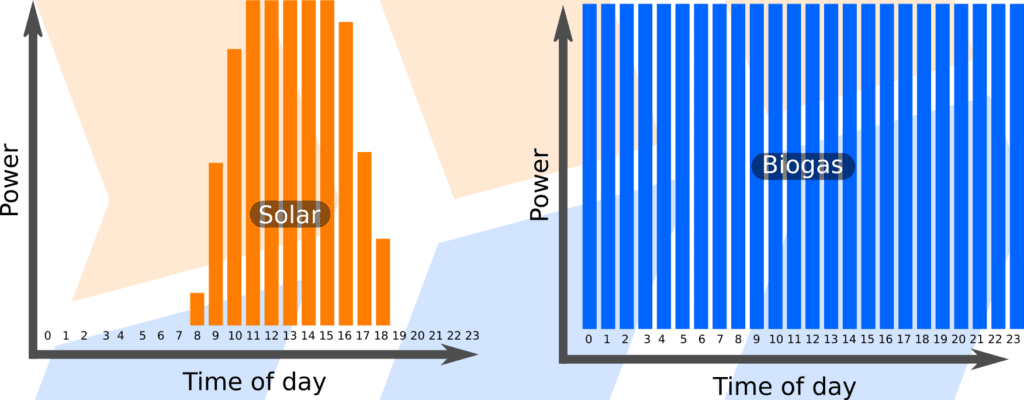

How is biogas different to other renewable energy?

Electricity generation from solar panels (photo voltaic) is only possible when there is sunshine. Wind turbines only produce electricity when the wind blows. Biogas can be stored and thus electricity can be generated on demand (24/7), making electricity generated from biogas “baseload power”. Furthermore, biogas can be upgraded, making it equivalent to natural gas, meaning it can be used for other applications such as vehicle fuel. Anaerobic digestion is more often than not also a waste treatment technology, solving waste problems while generating energy.

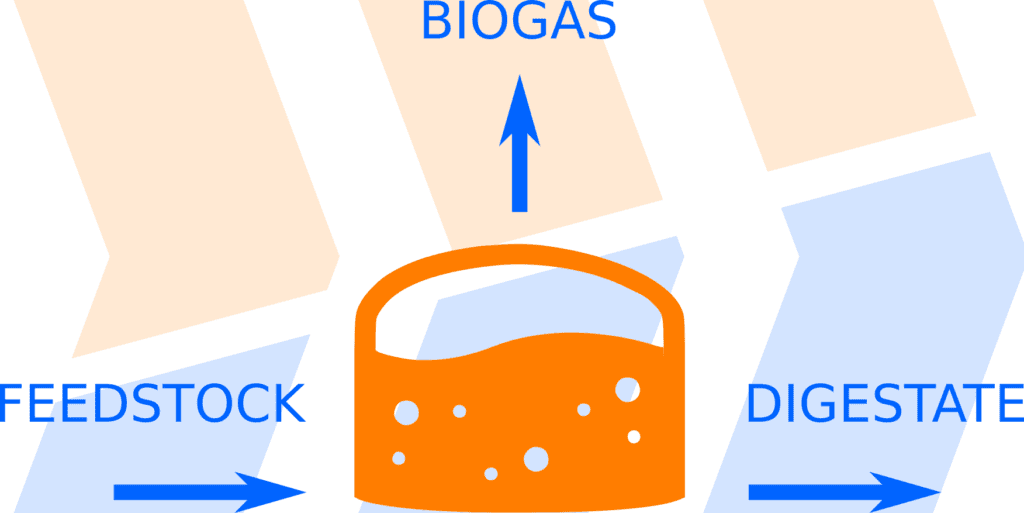

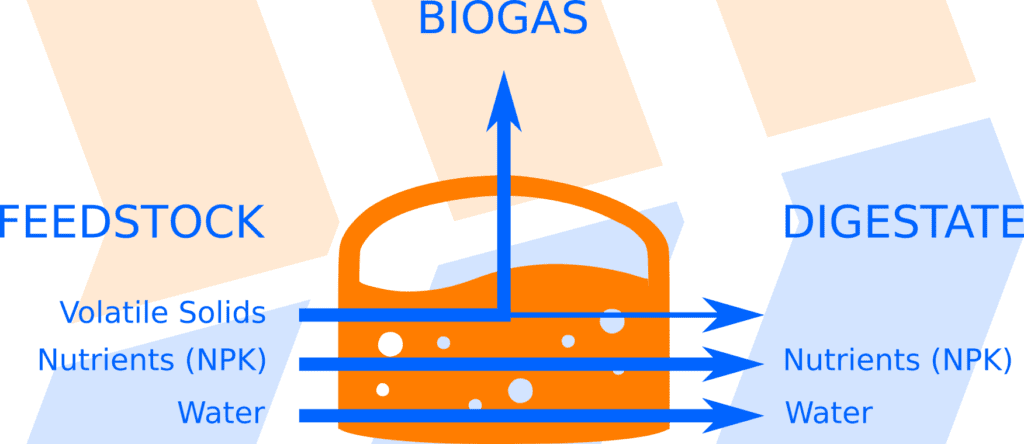

What is digestate?

Digestate is what is left over from the feedstock after digestion. The volatile organic matter in the feedstock is partially broken down to form the biogas. Water and inorganic matter (minerals/ash) and indigestible organic matter remain and form what is referred to as digestate.

Are the nutrients destroyed during digestion?

As the inputs are organic materials, they contain nutrients vital to life, such as nitrogen (N), potassium (K) and phosphorus (P), sulphur (S) and trace elements (various metals). These nutrients are not destroyed in the anaerobic digestion process, meaning the digestate is a valuable fertiliser.

What is anaerobic?

The absence of oxygen is a condition referred to as anaerobic.

What is anaerobic digestion?

Anaerobic digestion (AD for short) is an overarching term used to describe the process whereby biogas is formed. Metabolic activity of anaerobic microorganism (bacteria and archaea) turns volatile organic matter into mainly CH4 and CO2.

Is anaerobic digestion the same as composting?

No. Composting, by definition, is an aerobic process., that means it relies on the presence of oxygen. The metabolic pathways of the microorganisms involved in composting consume oxygen and generate CO2.

Where do the microorganisms come from that take part in the process?

Any organic waste placed in an anaerobic atmosphere will start to decompose thanks to microorganisms already present. To speed up the process, new biogas digesters are inoculated with seed material containing active microorganisms, usually from other anaerobic digesters or animal manure. Once a digester is active, the microorganisms do not need to be replenished.

At what temperature do digesters operate?

The relevant anaerobic microorganism thrive in two temperature bands, know as mesophilic (38-42°C) and thermophilic (50-55°C) temperatures.

What types of digesters are there?

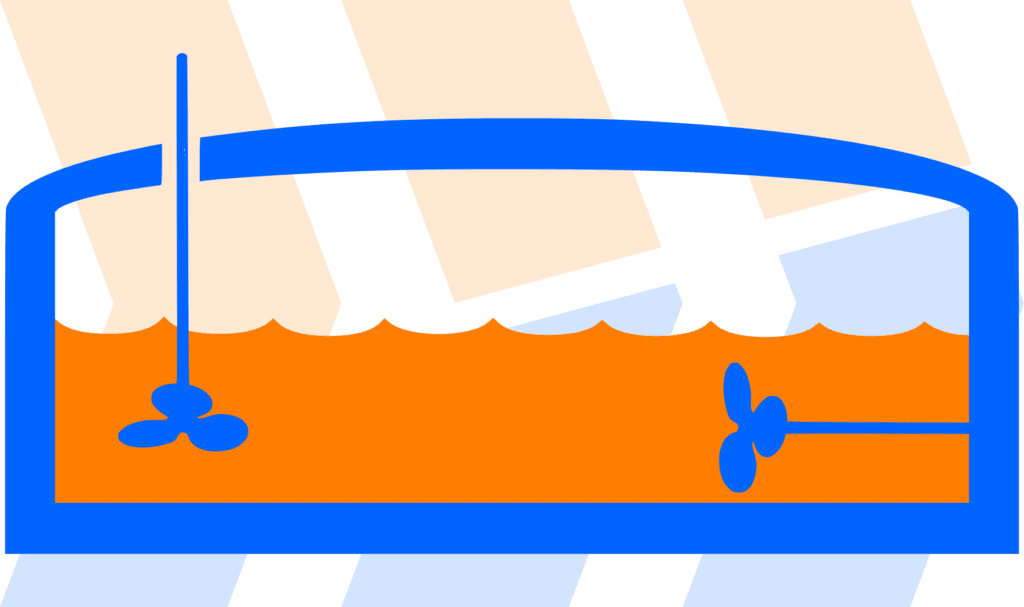

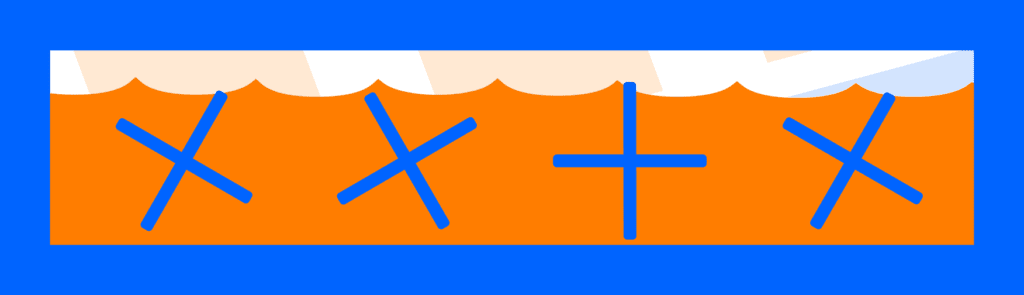

Digesters are typically described according to their fundamental operating principle. CSTR (Continuously Stirred Tank Reactor) and plug flow reactor are the two most common anaerobic digester, while fixed bed reactors (garage type) and lagoon digesters are less commonly used.

CSTRs are well-mixed vessels, ensuring that the entire volume is homogenous. Plug flow digesters are not well mixed, instead new material is added at one end of the reactor and moves towards the outlet by action of abstraction (i.e., old material from the outlet (“plug”) is removed when new fresh material displaces it in the reactor). Fixed bed reactors contain a stackable organic matter over which a biologically active leachate (liquid that has seeped out) is percolated. Lagoon digesters are typically large, making up for less efficient conversion by extended residence times.

What is wet and dry anaerobic digestion?

Wet and dry Anaerobic Digestion (AD) are ambiguous and inaccurate terms. Historically, CSTR’s were often referred to as wet digesters since the contents are flowable slurries. Plug flow digesters are often referred to as dry AD, however their contents are also flowable slurries, albeit less flowable than in CSTR’s. Garage type digesters are true dry digesters, in the sense that the material is stackable.